1800mm Large Mirror Polished Stainless Steel Decoration Ball

Our Services

Who are we?

Metal Garden Art Innovator. Creating Metal Art for You.

Create an artistic feature in your garden:

Looking for inspiration for your outdoor or indoor area or maybe just some more flavor to your house or garden? You might have a bare wall near a pool or alfresco area? Laser cut light boxes that can be back lit can create a stunning garden feature. We have a wide range of outdoor garden decorative spheres of various colors, laser-cut and bespoke sphere sculptures or sculpture of different shapes perfect and harmonious for every space around any corner in or outside your house or garden.

Whether you are an architect, landscape designer or interior designer with a project, it would a privilege and honor for us to provide the best service for you. We are intended to work for or with you to achieve the stunning and overwhelming impression on you. A wide range of materials from 304, 316 and 201 steel, mild steel, aluminum, iron along with powder coat or paint to comprehend your requirements on color.

FAQ

What are your finish option for a 6 Feet Mirror Polished Stainless Steel Hollow Ball with Base/Stand?

-- Yes, we offer a wide range of options to meet different requirements from our clients regarding size/diameter, thickness, color and material and so on. Options include: stainless 304 and 316 or 201, powder coat, paint, galvanized plate, or natural rust finish. Our powder coated finish has an undercoated zinc plate for outdoor use, which also eliminates the need for maintenance and rusting.

What is your lead time?

-- Our general lead time is 20-25 days but may extend during peak periods.

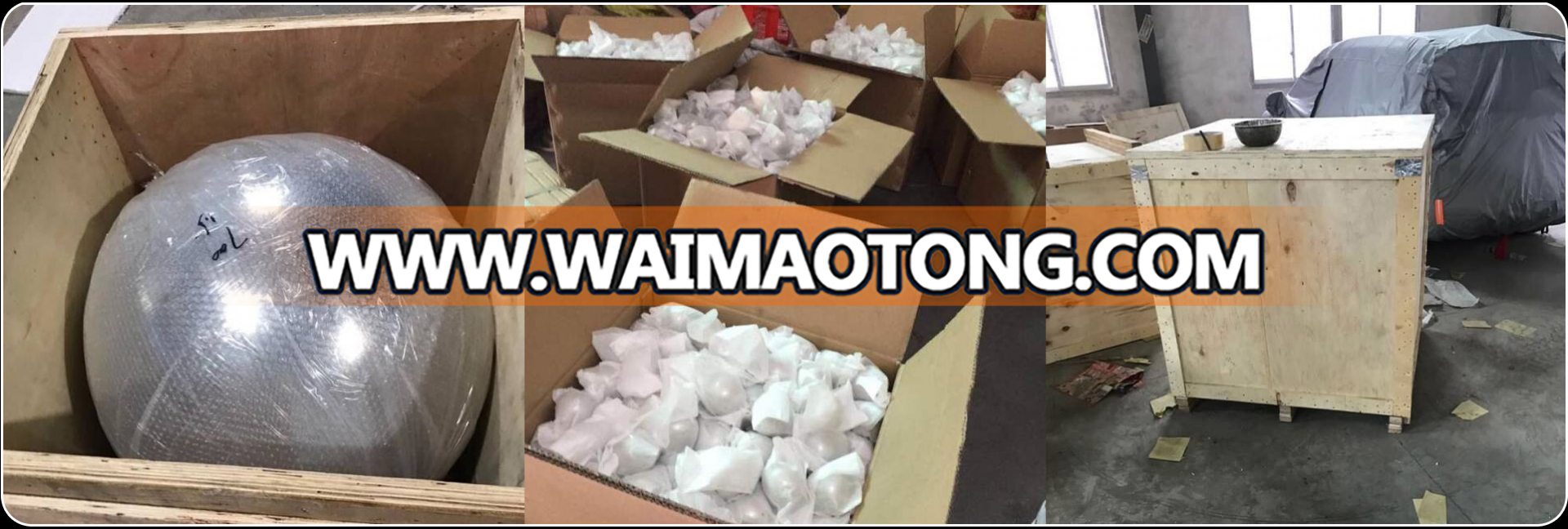

How do you pack a 6 Feet Mirror Polished Stainless Steel Hollow Ball with Base/Stand?

-- It will first be wrapped entirely with EPE. It will later be placed inside a wooden case with a protective tire on the bottom and buffering foam around.

What are the means of transport?

-- Air, sea or express delivery etc.

Product Description

Corrosion Resistance

Excellent in a wide range of atmospheric environments and many corrosive media. Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 60°C. Considered resistant to potable water with up to about 200mg/L chlorides at ambient temperatures, reducing to about 150mg/L at 60°C.

Heat Resistance

Good oxidation resistance in intermittent service to 870°C and in continuous service to 925°C. Continuous use of 304 in the 425-860°C range is not recommended if subsequent aqueous corrosion resistance is important. Grade 304L is more resistant to carbide precipitation and can be heated into the above temperature range.

Heat Treatment

Solution Treatment (Annealing) - Heat to 1010-1120°C and cool rapidly. These grades cannot be hardened by thermal treatment.

Welding

Excellent weldability by all standard fusion methods, both with and without filler metals. AS 1554.6 pre-qualifies welding of 304 with Grade 308 and 304L with 308L rods or electrodes (and with their high silicon equivalents). Heavy welded sections in Grade 304 may require post-weld annealing for maximum corrosion resistance. This is not required for Grade 304L. Grade 321 may also be used as an alternative to 304 if heavy section welding is required and post-weld heat treatment is not possible.

| AISI Number | C % | Si % | Mn % | Cr % | Ni % | Mo % | P % | S % | Character |

| AISI 302 | 0.15 Max | 1.00 Max | 2.00 Max | 17.0~ 19.0 | 8.0~ 10.5 | | 0.045 Max | 0.03 Max | Slightly magnetic Austinitic |

| AISI 304 | 0.07 Max | 1.00 Max | 2.00 Max | 17.0~ 19.0 | 8.50~ 10.5 | | 0.045 Max | 0.03 Max | Slightly magnetic Austinitic |

| AISI 316 | 0.07 Max | 1.00 Max | 2.00 Max | 16.5~ 18.5 | 10.5~ 13.5 | 2000~ 2.50 | 0.045 Max | 0.03 Max | Non magnetic Austinitic Excellent corrosion resistance |

| AISI 420J | 0.17~ 0.25 | 1.00 Max | 1.00 Max | 12.0~ 14.0 | | | 0.045 Max | 0.03 Max | magnetic Hardenable HRC 48 Min fair corrosion resistance |

| AISI 430 | 0.08 max | 1.00 Max | 1.00 Max | 15.5~ 17.5 | | | 0.045 Max | 0.03 Max | fair- good corrosion resistance |

| AISI 440C | 0.95~ 1.20 | 1.00 Max | 1.00 Max | 16.0~ 18.0 | | 0.40~ 0.80 | 0.04 Max | 0.02 Max | fair corrosion resistance Hardenable HRC 58 Min |

Packaging & Shipping

PACKAGES

Outside Packing:

Thick and standard wooden case with metal junction and nails. Pallet on the bottom.

Inside Packing:

Shake&Shock Proof.

Thick plastic or soft shockproof foam to avoid scratches on the surface of the product;

Cushioning tire on the bottom to prevent the item moving or tumbling or leaving dents on the product in case of rough transport.

SHIPPING

Modes of Shipment

Ground, Ship and Air

Ground:

Land or "ground" shipping can be by train or by truck. Ground transport is typically more affordable than air, but more expensive than sea especially in developing countries like India, where inland infrastructure is not the most effective way.

Shipment of cargo by trucks, directly from the shipper's place to the destination, is known as a door to door shipment and more formally as multimodal transport. Trucks and trains make deliveries to sea and air ports where cargo is moved in bulk.

Ship:

Much shipping is done aboard by actual ships. On rivers and canals, barges are often used to carry bulk cargo.

Air:

Cargo was transported by air in specialized cargo aircraft and in the luggage compartments of passenger aircraft. Air freight is typically the fastest mode for long distance freight transport, but also the most expensive.