2014 Good price SS304 316 201 30mm Mirror Polished Stainless Steel Ball/Whole Ball/Half Ball

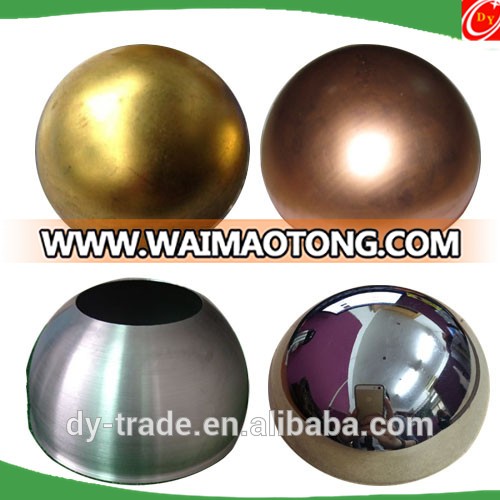

SS304 316 201 30mm Mirror Polished Stainless Steel Ball/Whole Ball/Half Ball

We are capable of providing stainless steel spheres/balls almost as per your specific requirements. Products include hollow stainless steel spheres (ranging from 6mm to 2500mm in diameter), available for delivery if we have it in stock or delivered within 15 days. Wall thickness of spheres varies from 0.4mm to 3mm. Shaped by water pressure, our products could be mirror polished without any seams noticeable on the surface; meanwhile, welding and then sandblasting spheres is a another way to produce mirror polished spheres also without detectable traces on the spheres. Having been offering services for our customers worldwide, a variety of products also fall under many categories of our products. Staidness steel spheres, hollow or solid, of all sizes are our major products, and brass and bronze balls come along. Hollow reflective stainless steel spheres of enormous sizes are amongst the top sales in our products. Perforated stainless steel spheres or sculptures of 304 or 316 are also our hot products. Not to mention we have done considerable amount of drilled stainless steel balls or spheres with holes of many sizes. Our products are of professional and advanced technology with cost-effective craftmanship and favorable delivery time.

Stainless steel sculpture packing:

Outside packing:

2CM standard wooden crate with metal junction and nails;

Enough wood chunks as support for the inner products;

Anti-shaking;

Three strong strapping packing belts around the wooden crate ;

Inner Packing:

Thick plastic or soft foam to avoid scratches on the surface of the ball;

Shockproof foam to protect each carved garden ball for decoration.

304

| TABLE3-LOW TEMPERATURE MECHANICAL PROPERTIES |

| Condition | Temperature ℉(℃) | UTS kSI.(MPa) | 0.2%YS ksi.(MPa) | Elongation% in 2"(50.8mm) |

| Annealed | _320(_196)) | 235(1620) | 56(386) | 40 |

| _80(_62) | 161(1110) | 50(345) | 57 |

| _40(_40) | 145(1000) | 48(331) | 60 |

| 32(0) | 122(841) | 40(296) | 65 |

| 70(21) | 85(586) | 35(241) | 55 |

316

Table 1. Composition ranges for 316 grade of stainless steels.

Grade | | C | Mn | Si | P | S | Cr | Mo | Ni | N |

316 | Min | - | - | - | 0 | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 |

316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 |

316H | Min | 0.04 | 0.04 | 0 | - | - | 16.0 | 2.00 | 10.0 | - |

max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | - |

Type 304 Stainless Steel is a variation of the base 18-8 grade, with a higher chromium and lower carbon content. The lower carbon content minimizes chromium carbide precipitation due to welding and its susceptibility to intergranular corrosion. In some instances Type 304 can be used in the "as-welded" condition. Type 304L is an extra low-carbon variation of Type 304 with a 0.03% maximum carbon content that eliminates carbide precipitation due to welding. As a result, this alloy can be used in the "as welded" condition, even in severe corrosive conditions. In many cases it eliminates the necessity of annealing weldments except for applications specifying stress relief. Type 304L has slightly lower mechanical properties than Type 304. High strength, excellent corrosion resistance and excellent formability make Types 304 and 304L Stainless Steels useful for many applications. Typical uses include architectural moldings and trim, kitchen equipment, as well as chemical, textile, paper, pharmaceutical and chemical industry processing equipment.For severely corrosive environments or when welding is required, Type 304L is preferred because of its greater immunity to inter-granular corrosion.

304 widely used in the market. Used in iatrical instrument, chemical industry, avigation. Plastic hardware: scent bottles, sprayers, valves, nail polish, switches, washing machine, fridges, air condition, medicinal materials, automotive fittings, bearing, nursing bottle and so on. A representative of Austenitic. Nonmagnetic, but magnetic after rolling. Magnetism can be rid of, HRC ≤ 26. Antirust and anticorrosive.

316 used in iatrical instruments, chemical industry, avigation, scent bottle, sprayer, valve, nail polish, mobile phone fittings. Austenitic. The best steel ball in the steel ball area, HRC ≤ 26. Better than 304. Can be used in personal decoration.

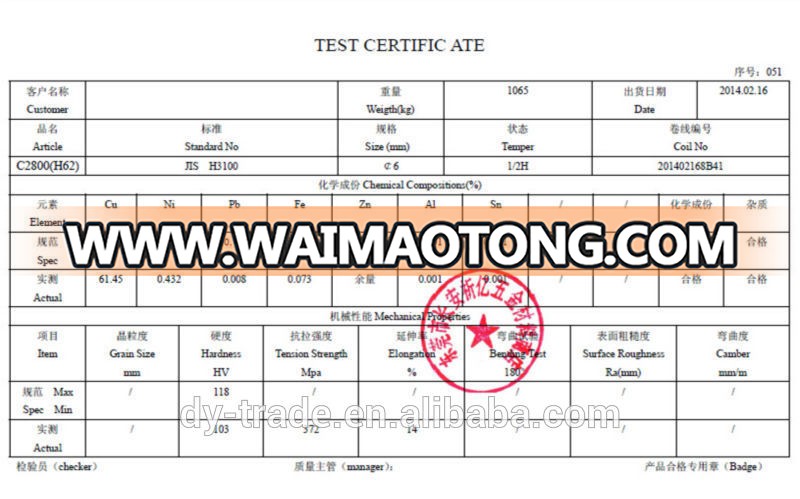

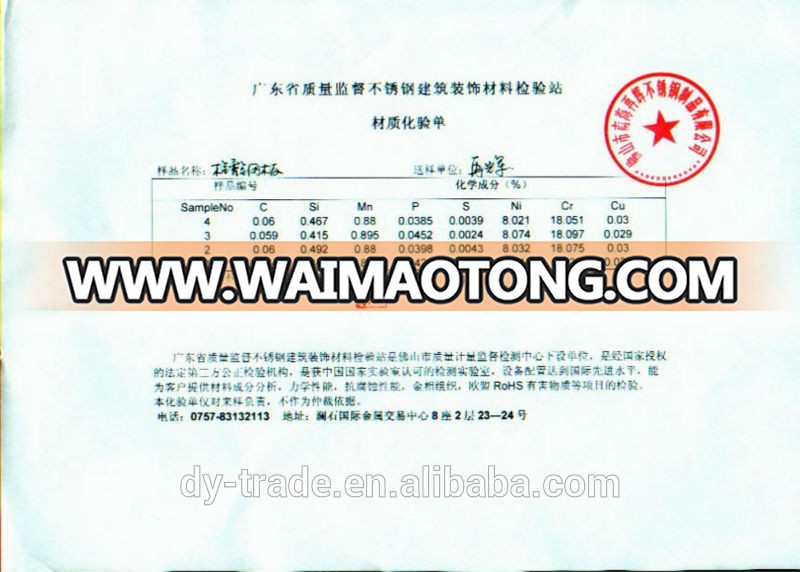

Authenticity

Certificate